One of the biggest challenges when working on brownfield and contaminated land sites is gathering high-quality geotechnical and geo-environmental data without putting people at risk from underground pollutants.

This challenge is not new, but the increasing urgency around environmental remediation and sustainable land use requires a fundamental shift in how we approach site investigations. The future of effective risk management lies not just in better tools, but in a more intelligent, integrated, and proactive methodology.

Traditional methods for contaminated land investigations, such as borehole drilling, often expose site staff to harmful substances and generate waste that must be transported, tested, and safely disposed of. This process can unintentionally spread contamination, even with strict protective measures in place. It is a method that is not only slow and costly but also misaligned with the goals of minimising environmental impact and protecting human health.

The power of dynamic investigation methods

The focus is shifting toward dynamic investigation methods that prioritise speed, safety, and data quality.

YOU MIGHT ALSO LIKE

For decades, cone penetration testing (CPT) has been a trusted method in this field, but its full potential is unlocked when combined with advanced tools like the membrane interface probe (MIP) and laser-induced fluorescence. This fusion of technologies allows investigators to quickly and accurately detect different types of hydrocarbon contamination with unprecedented precision.

The latest developments in this approach, using MIP, mean businesses can identify individual contaminants and apply these high-resolution methods to areas that are typically harder to characterise, such as plume edges and low-contamination zones. This level of detail is crucial for developing targeted and effective remediation strategies.

Non-invasive acquisition

The acquisition process is quick, quiet, and non-invasive, reaching depths of around 50 to 60m, depending on ground conditions encountered. Continuous data profiling eliminates the risk of missing anomalies in the vertical profiles.

With traditional methods, soil samples are collected and sent to a laboratory for chemical and geotechnical analysis, a process that can take weeks. Industry developments such as advanced CPT methods, in contrast, provide immediate, high-resolution data. Clients can see the site structure in real time, on-screen, as the cone advances downwards. This shift from a passive, post-fieldwork analysis to an active, real-time collaboration is significant for how decisions are made.

When an investigation also includes a cone like Fugro's Aquisense, clients gain an even deeper insight into the hydraulic properties of the subsurface. It helps businesses understand how groundwater moves through the soil and how easily it flows. This is a critical factor in predicting contaminant migration and designing effective containment or treatment systems.

These investigation methods deliver high-resolution data, meaning the readings are taken every centimetre, giving a very detailed image of the vertical profile of the ground. Because the data is available in real time, informed decisions can be made immediately onsite to adjust and improve the investigation as it happens.

Real-time data, 3D site modelling

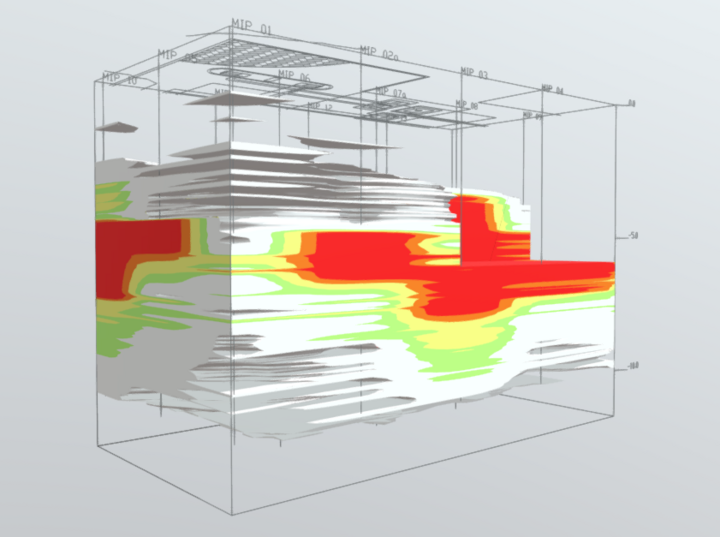

One of the biggest advantages of this approach is the ability to build a 3D model of the site. These models help businesses pinpoint where contamination is coming from and how it is spreading underground. They also show the relationship between the source and the surrounding area in a clear, visual way. This makes it easier to understand complex site conditions and supports better decision-making when planning clean-up strategies or meeting regulatory requirements.

The implications of this technology for project timelines and costs are profound. While traditional drilling methods may produce only 10 to 15m of material a day, CPT methods are up to 10 times faster. This dramatic increase in speed allows for a more comprehensive investigation within the same timeframe, or a faster turnaround for time-sensitive projects.

The resulting 3D site models can be delivered in a day or two, compared to the six to eight weeks often required for traditional methods that involve collecting, logging, and laboratory testing samples.

A more adaptable, comprehensive and cost-effective approach

Having access to more real-time data means businesses can decide how to adapt their investigation plans at pace based on preliminary findings. This not only makes the process more cost-effective but also allows for a more thorough investigation, focusing on specific risks that could otherwise result in costly issues down the line. Because these methods are more economical, it is possible to have more investigative locations per project, allowing for denser data grids, or wider coverage to track contaminant plumes. Both options provide a reliable basis to decrease risks.

This move toward more adaptable, comprehensive, and cost-effective approaches is not just about efficiency; it is about raising the standard of environmental protection.

An even better future

As technology advances, systems with increasingly automated features will drive further efficiencies, as well as safety benefits. Instead of manually connecting rods one by one, systems such as Fugro's Electric Deep Drive, an electric, coil-based rig system that uses a continuous coil up to 80m long, can be deployed without direct handling. Where sites require testing to be conducted remotely, such as in particularly hazardous or contaminated areas, conversion for remote operations is possible.

Conclusion

As an industry, we have an opportunity to redefine what is possible in environmental and geotechnical assessment by embracing new technologies. The industry's goal should be to move beyond traditional methods and adopt solutions that combine high-resolution, real-time data collection with advanced modelling and automation.

This transformation in how the industry understands and manages subsurface conditions will help clients reduce uncertainty, accelerate timelines, and make smarter, more cost-effective decisions, ultimately leading to a safer, more sustainable future.